|

Established in 1979 by Kenneth W. Wolter, Home Made Manufacturing was created with the vision of offering a wide range of high-quality power transmission components with a focus on innovation and flexibility. As a mechanical engineer, Ken worked as the Assistant Chief Engineer for a stamping company, and raced Formula One race cars on weekends. With a wealth of experience in manufacturing and a high demand for his custom gears, Ken embarked on the journey of developing a company distinguished by its use of state-of-the-art technology to set itself apart from competitors. HM is now led by his daughter, Nicole M. Wolter. She continues to carry on the legacy of producing innovative U.S.-made synchronous drive products at HM. While our initial focus was on the automotive industry, we have expanded our capabilities to meet the needs of several other industries including aerospace, defense, food and beverage, medical and more. For over 45 years, HM has remained a prominent player in the manufacturing industry. We asked Ken to remark on this accomplishment, to which he replied, "I can't believe I've been this stressed out for 45 years!" As we reflect on the last 45 years, we'd like to extend our sincerest gratitude to our customers, employees, and our community. The continual evolution and success of our small business is driven by your support, and for that we thank you. As we look to the future, we strive to push the limits of innovation, without forgetting where everything first began. Cheers to 45 years in the industry and many more to come!

0 Comments

One of my primary focuses as a woman in the manufacturing industry has always been to inspire other young women to get involved in the field. This year I had the pleasure of mentoring Julia Kraus, a Mechatronics Technology student.

Julia was an engineering intern at my company, where she focused on automation and the role it plays within engineering and manufacturing. Prior to being an engineering intern, Julia had intended to pursue a career in elementary education. She then discovered the Mechatronics Technology Certificate program at College of Lake County, and decided to take a deeper dive into the realm of engineering. During her time at HM Manufacturing, Inc. we were able to build upon the knowledge she gained from her studies, giving her practical, real-life experience. Julia spent the majority of the 4 month internship working on solidworks, reverse engineering parts for process flow prints, and automation. She also learned how to control and program our robot. For her final capstone project, she drew a full set of jaws in different ranges for our Okuma America Corporation live tooling lathe and RoboJob automation in order to run a multitude of diameter parts. "There's something different about learning these concepts in school and actually seeing them play out in the real world. Being an intern at HM has exposed me to the different areas of this business, and I feel like I've gotten a deeper understanding of what it takes to work in manufacturing. I've gained a lot more clarity in terms of what I would enjoy doing as a career." As Julia continues her journey to finding a career, it is my hope that she will carry the knowledge she gained during her time as an intern with her, and move forward with confidence knowing that she has built a strong foundation for herself. Thank you for all of your hard work this year, Julia. I am so proud of you and cannot wait to see what you will achieve in the future! We're proud to share that our president and CEO has recently been added to the Nuts, Bolts & Thingamajigs (NBT), the foundation of the Fabricators and Manufacturers Association (FMA) board of directors for a two-year term! To learn more about her goals, click here.

We are proud to share that our president, Nicole Wolter, has successfully completed her term as the first-ever Latina Board Chair of the Technology and Manufacturing Association (TMA). To read her farewell post, click here.

HM Manufacturing’s founder celebrated his 80th birthday this week. Ken Wolter started the business in 1979 out of the basement of his parents’ home, granting the company its name of HM (Home Made) Manufacturing. His passion for manufacturing stemmed from his interest in Formula 1.

Prior to 1979, he worked as the assistant chief engineer for a stamping company where he managed over 700 employees. In his free time on the weekends, Ken pursued Formula 1 racing, going all over the country to race and tinker with the gearbox in his car. While getting more and more familiar with the cars engineering and design aspects, Ken noticed a need for certain automotive parts to become more efficient. With a background in mechanical engineering, Ken was able to reconfigure these parts while creating pieces of his own to significantly improve the efficiency of the vehicle. Ken began traveling to different races where interest in his custom parts continued to grow. As more and more people inquired about his parts, he started to manufacture them out of his basement and sell them on the road. What began as a business in the automotive industry evolved into other power transmission components. As demand continued to increase for his custom gears, Ken opened the original 2,500 sqft shop in Schaumburg, IL. The business mainly serviced the automotive and printing industries. In the past 44 years, HM’s capabilities have expanded to service a wider range of industries while still serving the original industry that fueled the business. The company now operates out of a 15,000 sqft facility in Wauconda, IL and offers custom transmission components, along with engineering services. I was able to sit down with Ken today to talk to him about his biggest milestones throughout the history of the company and what he is most proud of. He shared with me that his continuous milestone, that also happens to be what he is most proud of, is the constant innovation that is prioritized at HM. Ken also added that he always stays on the cutting-edge of innovation when it comes to machines as well. The company was again one of the first to introduce CNC lathes to their facility. Ken is very proud of the business that he built and all the people here. He was kind enough to share with me a variety of the different approaches that continue to set HM apart and overall, be successful. In honor of his birthday, a few of the HM team members had some words to say about Ken. Our production manager, Adam, when asked about Ken said that he was “one of the most intelligent individuals I’ve ever worked with. He’s someone with knowledge about everything and there’s nothing he doesn’t know.” Linda, who works in our customer service department, also shared that “as a newer member of the team, I’ve found that working with Ken has taught me more about manufacturing than I’ve ever thought to know. I love that you can count on him to help with any issue that arises. He’s a hands-on type of person who always has time to answer your questions.” Not to mention, “he’s dedicated and truly cares about his employees,” says John, another HM team member who is the lead in the lathe department. Our team members are proud to be a part of an organization that was created by someone who is a role model to all. We are grateful to be able to celebrate Ken’s birthday with him and continue to help grow his vision even more. Happy birthday, Ken! Our new Robo-Job Lathe-Assist Essential robot has officially landed in our shop. This new robot aids our Okuma lathe in more capacity and allows for larger production runs. We can’t wait to see the new improvements that this robot will provide. The manufacturing industry is advancing in both automation and technology and we are fortunate to be a part of this growth towards an impressive future.

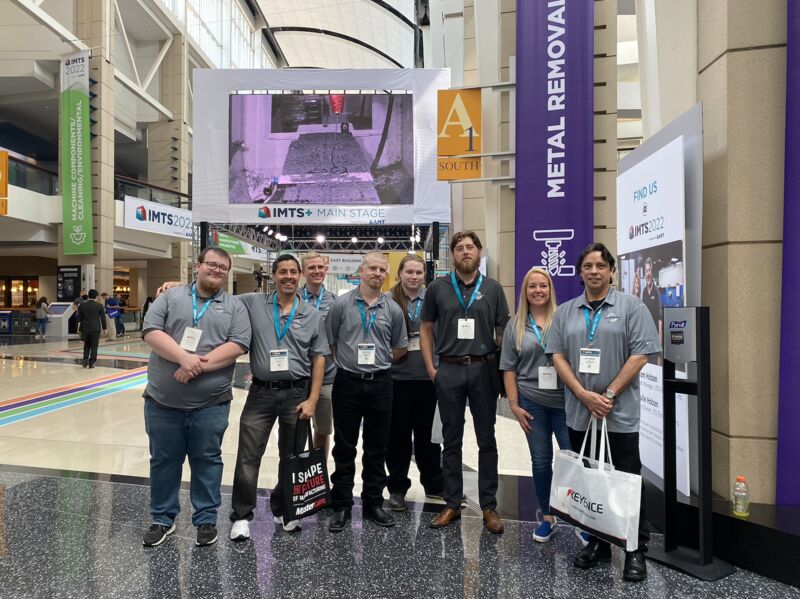

HM Manufacturing purchased a new GENOS M460-VE Mill to add to our improved capabilities of our business. This mill was purchased at IMTS 2022.

President and CEO, Nicole Wolter, joins the Making Chips Podcast as this season’s new host. Throughout this season she will be discussing a variety of different topics with other influential people within the manufacturing industry.

CEO, Nicole Wolter, joined Andrew Crowe and Chris Czarnik to continue their discussion from their IMTS 2022 JobShop Workshop. They spoke about the value of appealing to a younger audience and what approaches can be taken in order to get those interested in the manufacturing industry. Nicole also spoke about her personal philosophy with paid internships and the importance of showcasing the exciting and innovative aspects of our industry over social media.

Click here to watch the full video: https://www.imts.com/watch/video-details/Workforce-Development-and-Retention-Part-2/347 What a week at IMTS 2022!

The team at HM Manufacturing had an incredible week at IMTS 2022. The show was very busy and it was great to be able to see old friends and meet many new people. The large amount of innovation and technology showcased the exciting places our industry is headed. President and CEO, Nicole Wolter, spoke at many events throughout the week discussing a variety of different topics. On Monday, Nicole spoke alongside Andrew Crowe and Chris Czarnik to discuss workforce development and retention at the IMTS Job Shop Workshop. Formatted like a Ted Talk, the three spoke on the issues in front of an audience and answered questions at the end from the crowd. The session was very insightful and had many meaningful thoughts from all three panelists. Over at the Okuma booth, Production Specialist, Wade Anderson, invited Nicole to speak on the podcast and talk about her background along with the purpose of attending IMTS. The full podcast will be out on Okuma’s platforms soon. Not to mention, NTD News interviewed Nicole for a segment on their channel about using social media resources and trends to recruit new members to the workforce. Nicole is a strong believer in using platforms such as Instagram and TikTok to appeal to a younger generation. Marley led a discussion between Nicole and Anessa Muthana on the IMTS Main Stage on Wednesday afternoon. The three talked about what they had seen at IMTS so far and what they hope young women can take away from the event. Both also touched on what it was like to take over a family business and what it meant to them to continue their family’s legacy. Along with that, Marley specifically asked Nicole to speak on how investing in technology helps recruit and retain a younger workforce. The entire main stage session will be available through IMTS. A busy day on Thursday included a session about cell phone etiquette for Edge Factor in the Student Summit section of IMTS. This short interview talked about the appropriate way to use your cellphone in both the classroom and the workplace. Not only that, Nicole spoke with three others on issues facing women in technology. This group of women spoke for over an hour and answered audience questions regarding their discussion. Nicole was also delighted to speak with Milachi Greb, of Elite Automation, to highlight her background and how she got into the manufacturing industry. The two had an insightful discussion, and the full interview will be up on Elite Automation’s platform. As the week came to a close, the entire HM Manufacturing team came to IMTS on Friday to explore the various different booths and spot anything they believed could aid in the production on the plant floor. We ended the day with a team lunch where we were able to discuss everything that was seen and any ideas that they had. Team member, Eric Taylor, found many interesting aspects including a vice fixture that could pick up gears of any shape. Our whole team had a great time at IMTS 2022 and we cannot wait to be back in two years! |

HM BLOG |

- Products

- Capabilities

- Industries

-

Catalog

- 3M SERIES HTD

- 5M SERIES HTD

- AT5 SERIES PULLEY STOCK

- AT10 SERIES PULLEY STOCK

- AT10 SERIES PULLEY STOCK

- L SERIES PULLEY STOCK

- T5 SERIES PULLEY STOCK

- AT10 SERIES PULLEY STOCK

- 8M SERIES HTD

- 8M RPP PANTHER QT POWERCHAIN

- H SERIES PULLEY STOCK

- MXL SERIES PULLEY STOCK

- XL SERIES PULLEY STOCK

- 3M SERIES GT

- 5M SERIES GT

- 8M SERIES GT

- News

- About

- Contact

|

Contact Us1200 Henri Drive

Wauconda IL 60084 Phone: (847) 487-8700 Fax: (847) 487-8707 |

ConnectCopyright © 2018

HM Manufacturing |